Data Analytics in Manufacturing and Logistics Management

2019-06-07

As the lifeblood of intelligent manufacturing and smart logistics management, Big Data must be appropriately harnessed to yield the desired added value. Data analytics has become an indispensable tool for optimizing and automating manufacturing processes and logistics (supply chain management). Besides data analytics, data visualization and data security belong among the crucial areas any manufacturing or logistics enterprise should embrace in the era of Smart Industry.

Smart Industry systems and digital technologies have opened up a whole new dimension of data analytics in manufacturing and logistics (supply chain) management. The results of collected and analysed data are now available in real time, leading to significantly faster decision-making processes and responses to unexpected or unscheduled events. Smart Industry systems pre-process and evaluate data so that designated personnel can have all the details they need to make a qualified and quick decision.

Thanks to such technology, mid- and low-level managers can react adequately to emergency situations in a timely manner, or even prevent their occurrence. But data analytics also allows Smart Industry systems built on the principles of cyber-physical production systems to be equipped with embedded auto-regulation.

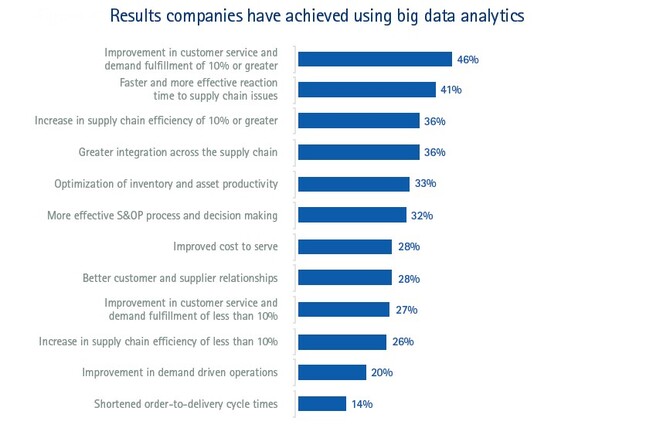

Results companies have achieved using big data analytics (source: Accenture)

The digital twin is another technology in intelligent manufacturing and smart logistics (supply chain management) fuelled by data analytics. A digital twin is a virtual copy of a factory’s machinery, data, processes, systems, production lines, or the entire factory. A digital twin operates with exact, real-time and historic data, which is why it is useful for simulation models to identify bottlenecks – places of diminished operating efficiency in the manufacturing flow – or for prediction, most notably in enterprise asset management (EAM).

Even though predictive analysis is just finding its way into manufacturing enterprises and logistics management, it will be replaced by prescriptive analysis in the not-so-distant future. Prescriptive analysis uses tools such as simulations, artificial neural networks and machine learning to provide a complex analysis of an event.

While predictive analysis reveals what and when something might happen, prescriptive analysis identifies the reasons for an outcome and what actions can be beneficial – for example, diagnosing future risks and opportunities and simultaneously offering recommendations that take into account the probable consequences of potential decisions.

The wider expansion and mainstreaming of artificial intelligence, machine learning and deep learning will find further applications in manufacturing enterprises and logistics (supply chain) management, most notably in processes related to enterprise asset management (EAM) and quality control.

Embedded analytics is another coming trend that digital factories (Smart Factories), manufacturing enterprises and supply chain (logistics) management will embrace. Manufacturing and transportation equipment will be outfitted with their own algorithms, thus upgrading them with auto-diagnostics functionality and toolsets. Machines and equipment will automatically analyse their own operations, leading in turn to autonomous adoption of improved processes.

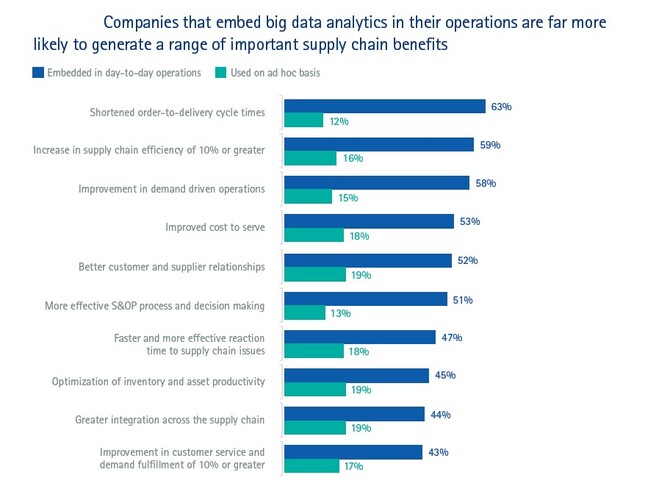

Big Data analytics-generated benefits in supply chains (source: Accenture)

Data Visualization

An indispensable part of data analytics is the distribution of the right data to the relevant group of employees at the right time. Personnel with decision-making rights need to have access to quickly understandable data and analyses that, in most cases, are based on verified models of user experience (UX) and intuitive forms of visualization (such as ANDON systems).

In regard to the rising tendency for client service customization, increased customization, dynamic and agile manufacturing and supply chain (logistics) management, data visualization is being increasingly adopted, even at the level of factory operators. This has led leads to broader data democratisation in factories and enterprises.

Besides the ability to see technical documentation and standard operating procedures on their workstations and production lines, operators can access additional information and insights regarding the details of a particular product.

ANASOFT implemented its Smart Industry solution EMANS, to optimize the picking process and outbound logistics in a distribution company where picking orders were displayed on workstation terminals. In addition, each order specified the client´s expectations, adding a new layer to the customer service requirements. As a result, the terminals show not only an item list and quantities, but also visualize contextual information that significantly reduces returns of delivered orders without increasing workloads or operating costs.

The trend of virtual assistants is gaining steam and will have a notable impact on the industrial environment and supply chain management. Ever-improving natural language interfaces will enable workers to control enterprise information and Smart Industry systems via voice (voice-controlled human-machine interface). Virtual assistants will be capable of providing required information verbally.

Besides data democratization within an enterprise or factory, data will be transformed into multimedia formats so that any required data (information, knowledge) will be provided in the preferred form, which may differ based on who needs what.

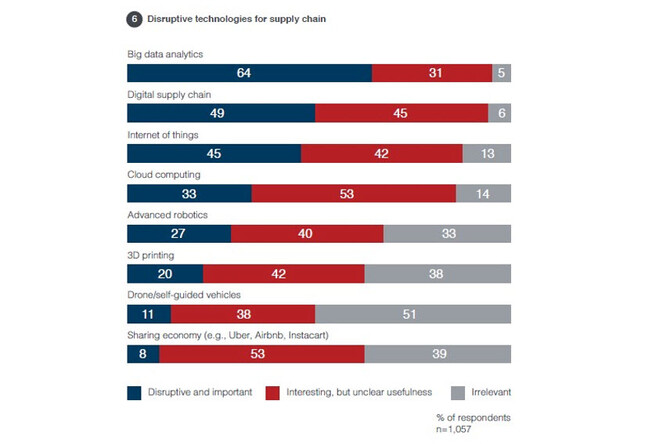

Disruptive Technologies for Supply Chain (source: SCM World)

Data Security

With more quantities of data becoming available and the rising number machines and equipment connected into the industrial Internet of Things (IIoT), threats of cyberattack or breaches of enterprise data are also on the rise.

Therefore, companies should pay more attention to security measures in order to protect personal, industrial and sensitive business data as well as machinery and equipment. Stored enterprise data in databases, data stores and file servers must be protected – for example, by independent network access monitoring and firewalls that flag suspicious transactions and database intrusions.

With respect to the protection of personal data, companies are legally obliged to adopt sufficient forms of securitization via selective anonymization or pseudonymization in their internal reporting or publication of analyses to protect information and prevent unauthorized use, or by implementing security solutions that allow anomalies to be detected.

Theft by authorized users, or carelessness, negligence (infection of informational technologies) by employees are among the most common forms of data abuse. On the other hand, Data Leakage Prevention (DLP) security solutions can prevent such internal data breaches.

Manufacturing enterprises and supply chains need to protect not only their information systems and equipment (PLC) but the whole IT infrastructure, since the complex Internet of Things (IoT) networks are susceptible to non-authorized intervention.

Besides firewalls to protect a company´s IT perimeter, manufacturing enterprises and supply chains need to secure themselves against unauthorized interference as a preventative measure against sabotage or the involuntary endangering of manufacturing processes, equipment or the supply chain.

Contemporary security solutions are outfitted with a wide variety of SCADA protocols and, along with Advanced Threat Prevention technology, are suitable even for the most demanding industrial environments.

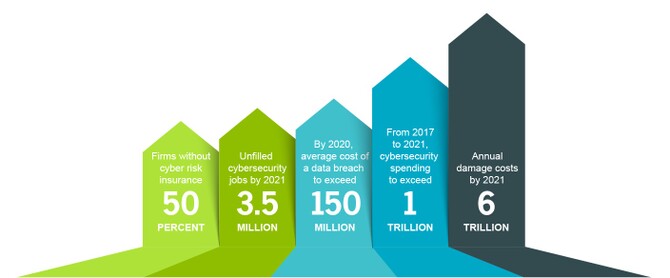

Cybersecurity Statistics (source: CSO, Cybersecurity Ventures)

read more