Actual paperless production becomes reality - EMANS

2016-11-04

The World Paper Free Day - on November 4, 2016

In accordance with the principles of sustainable development, people are increasingly concerned with the elimination of paper.

In accordance with the principles of sustainable development, people are increasingly concerned with the elimination of paper.

It is suggested also by many initiatives that encourage people and businesses worldwide to reduce paper consumption.

This way of thinking is close also to us, in ANASOFT. Through our SMART solutions we have brought the paperless reality in many sectors where we have successfully replaced standard paper processes.

Today, on November 4, 2016, when we are celebrating the World Paper Free Day, we have selected a few tips for paperless processes in production with our Manufacturing Execution Systems EMANS.

1. Collecting and gathering data from the production electronically

At today's level of automation it is natural that managers exchange amounts of data with individual production facilities.

The fact that there are reserves regarding paper wasting also outside the traditional office is showed by the high percentage of manufacturing companies that report production data in paper forms.

EMANS solution brings an opportunity to acquire and monitor data from the production online.

By implementing the automatic monitoring of production processes, the manual filing of documents and reports is eliminated.

It does not only save paper, but this solution also provides online access to information on the use of production resources, reliable long-term archiving of data with the possibility of comfortable search and quick export.

2. Dispatching and distribution of production orders electronically

The manufacture of products with high variability, there are several variants of assembly operation sequence chain. In addition, these variants are frequently altered. So that workers could respond quickly and easily to changes in the production process, EMANS offers a tool for the visualization of data and documents necessary for a manufacturing operations realization directly on a monitor at each assembly location.

An assembly screen displays a current assembly step and other information to the operator (e.g. an order number). Individual parts of the screen can be changed using the parameters. It means that at each step of assembly process it is possible to set for example a text with instructions, animation and image, or to change the parameters displayed on the right side of screen. This is enabled by the tool for the creation of Business Process Modeler - BPM.

An assembly screen displays a current assembly step and other information to the operator (e.g. an order number). Individual parts of the screen can be changed using the parameters. It means that at each step of assembly process it is possible to set for example a text with instructions, animation and image, or to change the parameters displayed on the right side of screen. This is enabled by the tool for the creation of Business Process Modeler - BPM.

By activating such model, the production process can be quickly and easily configured and managed. A clear graphical representation of the process makes it possible to introduce changes in real time without having to stop the production. Thereby you will ensure electronically not only the process management of production itself, but also operational and detailed production planning.

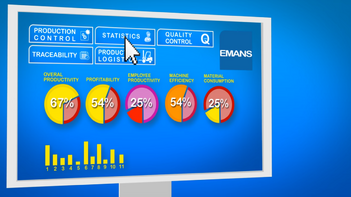

3. Fast and accurate assessment of key indicators

To have true and accurate information is the first step in the implementation of sustainable production. EMANS evaluates supporting documents for the key indicators of production quickly and accurately.

The manufacturing process is monitored automatically, and it provides information on the capacity utilization of production equipment in a transparent electronic form.

The manufacturing process is monitored automatically, and it provides information on the capacity utilization of production equipment in a transparent electronic form.

EMANS provides a dashboard to display the number of correctly manufactured units and rejects, and it helps to automatically analyse the reason of reduced production capacity (types of downtime, duration, ...).

Operators can thus be informed in a greater extent about the achieved actual performance in comparison to the plan.

4. Digital elimination of error rate in the production

Nowadays, quality is one of the basic requirements for the production, whether it is the quality of input components, assemblies or finished product. In terms of costs it is important to maintain the quality of the product for the first time so that it is not necessary to carry out the repairs of the product additionally. It prevents the formation of scrap, significantly increasing material costs but also reducing the production efficiency.

In a survey the ANASOFT company conducted last year, 15% of respondents said that they monitored the product quality by the visual inspection of randomly selected piece, and recorded the result in paper forms. Only 10% of respondents use a predictive evaluation system preventing the lack of quality in the production. However, despite this fact, we can observe a growing trend of digitization also in the field of quality in manufacturing plants.

In a survey the ANASOFT company conducted last year, 15% of respondents said that they monitored the product quality by the visual inspection of randomly selected piece, and recorded the result in paper forms. Only 10% of respondents use a predictive evaluation system preventing the lack of quality in the production. However, despite this fact, we can observe a growing trend of digitization also in the field of quality in manufacturing plants.

EMANS solution provides a tool which automatically controls the individual production process steps. The elimination of defective products based on ongoing inspections is ensured by the applied control mechanisms. The system checks whether a worker carries out orders according to a plan, monitors operations being executed, or also the order of their execution. Sensors monitor various details; for example not only if all screws were screwed, but also how strongly they were tightened. Unless this step is done perfectly, the system does not allow the worker to continue. The result? 100% quality of products.

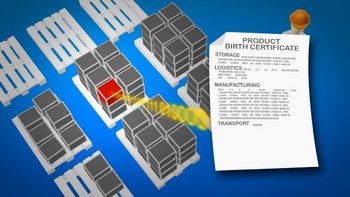

5. Digital birth certificate of product

Monitoring the parameters during the product manufacture and entering them in the product´s birth certificate is mainly used in the automotive industry. EMANS has a tool also for this area that eliminates the need to use paper forms.

During a production EMANS collects all relevant data relating to a product and ongoing operations. This is very valuable manufacturing evidence, the data containing the measured parameters from a production layer, used materials and components, sensory images, photos and many other data.

During a production EMANS collects all relevant data relating to a product and ongoing operations. This is very valuable manufacturing evidence, the data containing the measured parameters from a production layer, used materials and components, sensory images, photos and many other data.

The EMANS solution unique architecture allows unlimited data collection during the production, enabling you to register, identify and archive all activities in the production.

In addition to parameters and used materials monitoring, it is also possible to keep track of production progress (who, when, what kind of operation was performed), the test results including the measurement results saving, disagreements arisen and way they were addressed, all production documentation, the manufacturing conditions (pressure, temperature , screw torques) and many other parameters. After the manufacture completion it can be then detected where the given product or semi-finished product was used or sold, and its production parameters (by a batch or serial number).

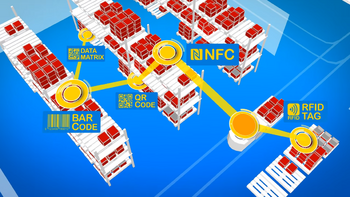

6. Management and allocation of production resources digitally

Warehouse management reduces the error rate caused by a human factor, and greatly reduces paper forms. For example, already in the process of picking EMANS can greatly simplify the work of the operator. Pick by Light technology guides the operator by means of light signals determining the right position with a right component.

The operator does not need to scan bar codes and has both hands free for handling goods.

The operator does not need to scan bar codes and has both hands free for handling goods.

EMANS also monitors whether there is sufficient supply of goods for the required expenditures in stock.

If the stock falls below the set level, EMANS will automatically plan the transfer of goods to replenish a relevant stock position, and the task is assigned to a particular warehouse operator.

As the storage operations are usually performed by mobile terminals, it is possible to measure and evaluate warehouse workers´ performance. Thus it provides sufficient good quality information to management personnel, needed for the evaluation, planning and improving of warehouse processes.

YOU MIGHT ALSO BE INTERESTED IN

- Trends in Logistics

- Industry 4.0 the Main Topic at the Davos World Economic Forum

- Jump on the Wave of the Fourth Industrial Revolution Today

- The Fourth Industrial Revolution Has Already Begun

- Will the fifth industrial revolution save the world?

- 3 Unknown Ways to Use Kinect

- How to Manage with a Shortage of Skilled Labor

- Tips for improving productivity in manufacturing