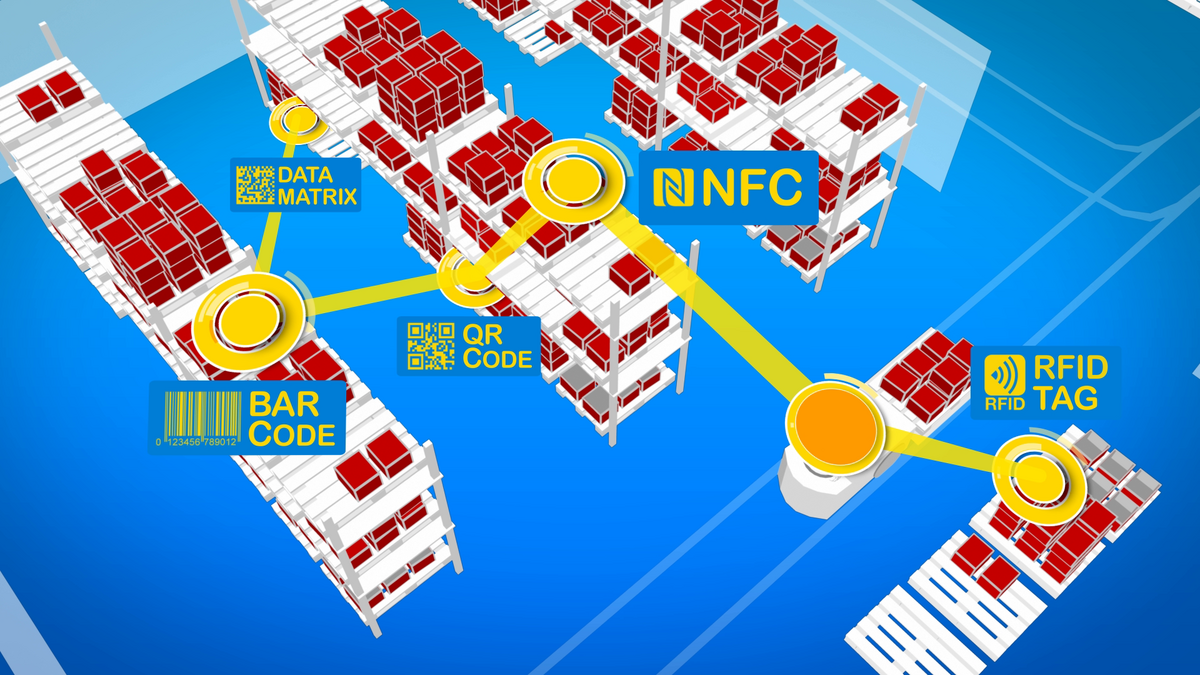

Real Time Locating System

The RFID technology is used for contactless identification of personnel, carts and parts. It eliminates the time needed for logging of operators at the workplace, and also eliminates the scanning of parts during the inspection of the assembly.

Utilization

- Monitoring the location of assets, goods and personnel in real time

- Scanning of RFID tags locations inside buildings or premises within a distance of 50 m.

- Reading and writing of information stored in the tag.

We have experience in deploying this technology in the demanding segment of the automotive industry. In these operations, where most operators handle high-value instruments and products, we meet the need for contactless identification of materials and operators.

The principle is simple: on the processed part or cart is affixed an active RFID tag that transmits a signal. The signal is received by a receiver, which transmits the signal via the LAN to the control computer.

Advantages of the RFID

- Reduces the identification time

- Eliminates the need for contact with the processed part

- Possibility to identify multiple items simultaneously

- Reduction in error rate

- Possibility to store information

- No need for direct line of sight to tags