Achieve Operational Excellence with Smart Industry Solution EMANS

KICKOFF YOUR DIGITAL AUTOMATION AND INDUSTRY 4.0 TODAY

The Smart Industry platform EMANS controls the company's technological, material, labor, data, equipment, and system resources. Thanks to the accurate and timely orchestration of enterprise operations and processes, the system EMANS ensures improved productivity performance, extended production capacity, and effective accomplishment of business goals in shifting markets and environments.

INTERNET OF THINGS AND SERVICES | IOT

BIG DATA

DIGITAL TWINS

ARTIFICIAL INTELLIGENCE | AI

transform your business into a smart enterprise

„As a Tier 1 supplier for the largest automotive companies, we guarantee the highest conformity of wheel assembly parameters on our autonomous production line with an average production cycle of 20 seconds per finished wheel. The detailed traceability of all manufactured wheels and their technical parameters are monitored and detailed by EMANS MES, which also ensures the conformity of all production parameters alongside the precise and timely fulfillment of the production plan“

Tomáš Halenár, Manufacturing Manager

DIGITALIZATION 4.0

The operations management platform EMANS deploys digital twin technology and artificial intelligence pushing manufacturing and enterprise automation to the next level. In addition to automating mid-management decision-making, the system EMANS ensures an increase in the overall enterprise performance.

Our smart industry experts on digital transformation and intelligent automation will gladly advise you.

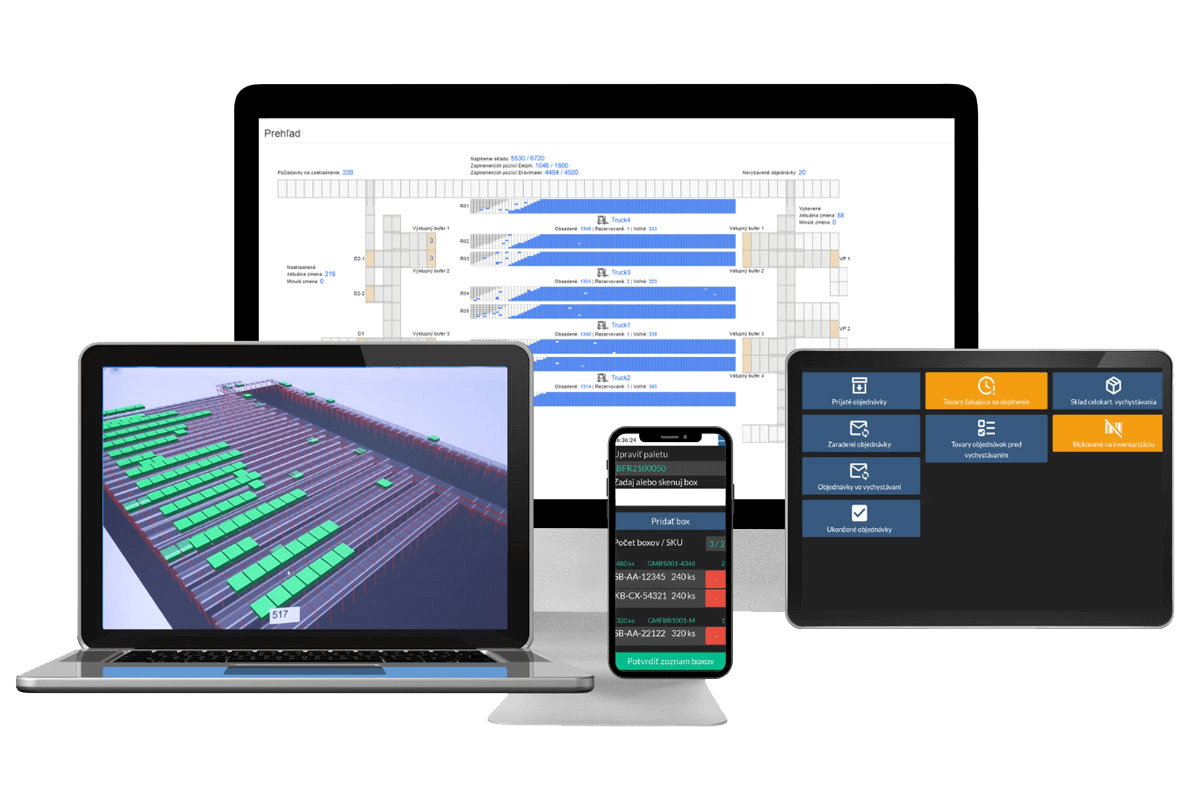

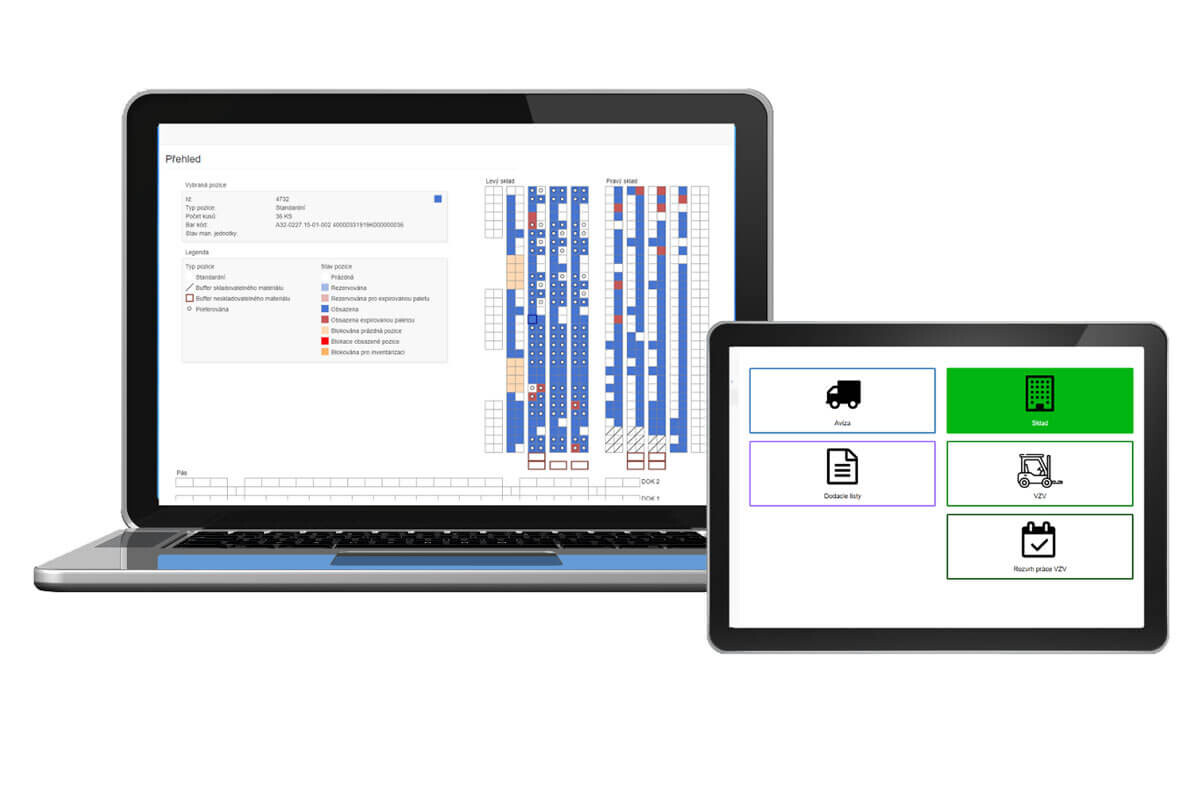

SMART wArehousing and autonomous feeding | EMANS WMS

EMANS WMS|WES accelerates order picking, utilizes enterprise resources efficiently, and expands warehouse throughput while streamlining logistics operations and optimizing operating costs.

- Agile warehouse management hybrid order picking

- Automated Just-in-Time operational strategies

- Dynamic Milk-Run and e-Kanban

- Autonomous control of synchronous flows

- Intelligent in-plant and external logistics

INTELlIGENT manufacturing AUTOMATIon | EMANS MES

Innovative manufacturing operations platform, EMANS MES delivers operational excellence to the factory.

- Streamlining of manufacturing operations

- Agility increase of process management

- Improvement of equipment and tool productivity

- Shortening of production cycles

- Predictive asset maintenance

OEE 4.0 for expanded production performance | EMANS OEE

OEE 4.0 augments the machinery and operational intelligence through production data. Real-time monitoring of manufacturing equipment and analysis of their data strengthen process management and improve operational performance.

- Maximization of equipment performance

- Elimination of breakdowns and unplanned downtimes

- Energy consumption and waste production elimination

- Detailed manufacturing data monitoring and reporting

- Continuous asset condition monitoring

- Increase of production capacity and manufacturing cost optimization

„The intelligent logistics system EMANS WES controls complex warehousing processes in our distribution center, ensuring that every customer order is picked up within a few minutes. Fresh fruit and vegetables shipped in volumes of up to 28,000 crates per day are thus delivered unto store counters within 24 hours after the harvest at local growers“

Daniel Sabel, Project Director

we can help you with

Development and Integration of Smart Industry Solutions

Logistics Studies

and Audits

Intelligent Automation

Consultation

Do you need advice about manufacturing automation or smart logistics?

industry accolades

„The system EMANS MES/WES from ANASOFT manages the supply of material for the largest domestic automotive factory plant in real-time, the exact deliveries of the right components are ready for dispatch unto the production lines within 17 minutes of placing the order“

Lubos Konopeus, IT Manager

Schnellecke Logistics

„Thanks to the new operations management system EMANS WES from ANASOFT, we could expand our portfolio of 3,000 different items of fresh food as well as pick large-volume orders for B2B customers and low-item orders for households with same-day delivery in annual volumes of over 50,000 tons“

Stanislav Petrula, CEO

Lunys

„In Dedoles, we planned a massive international expansion, for which we needed to be adapted not solely to marketing, but especially all inventory and warehousing processes. Thanks to Anasoft's intelligent warehouse execution management system and warehouse logistics solutions, we are efficiently running multi-channel retail for 20 European countries“

Jaroslav Chrapko, CEO

Dedoles