Acceleration in Warehouse Automation, Supply Chain and Order Fulfillment

2020-07-15

Supply and distribution demands are changing swiftly, as is the development of intelligent management systems. New technologies from the depository of Industry 4.0 based on the tools of Internet of Things (IoT), Internet of Services (IoS), virtualization, and artificial intelligence (AI) are already enabling a generational swing in inventory and warehouse management, and supply chain to meet the complex demands of omnichannel distribution. The rising WES systems [Warehouse Execution System] are part of this generational change.

The accelerated expansion of the internet economy (e-Commerce/e-Business) is radically changing its market and the entire supply chain. Consumer experience concerning the speed of Internet services is exerting pressure on the quality of sale services. This leads to increased material flow in logistics processes and the consequent shortening of order pick-up cycles and delivery times.

Distribution warehouse operators are often among the pioneers of automation. This is not only due to efforts to optimize operating costs but also the relatively high repeatability in warehousing activities. Robotization of warehouse processes via introducing automatic sorters, packaging equipment, or warehouse palletizing technology increases productivity and optimizes warehouse space capacity.

New technologies from Industry 4.0 — based primarily on the Internet of Things (IoT), the Internet of Services (IoS), virtualization, and the tools of artificial intelligence (AI) — are now enabling a generational shift forward in warehousing, supply chain processes and order fulfillment. These technologies bring a new form of digitalization, which lead to the bridging of the physical and virtual environment, thus the interconnection of devices and equipment with management systems (software) and human resources.

Distribution companies and warehouse operations can transform their processes and services thanks to new technologies. These technologies even enable them to expand their portfolio with additional services such as order completion, labeling and repackaging of orders, or quality control for incoming inventory and dispatched orders.

In this context, existing transhipments and repositories of inventory and materials are being transformed into modern autonomous units and supply chain nodes with adequate logistics reverse flows and material back-handling functionalities while meeting other criteria and standards of omnichannel distribution.

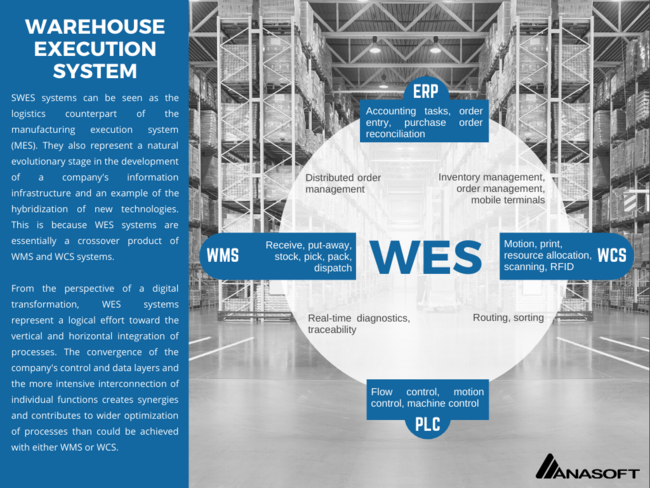

Not so long ago, order-picking and inventory management processes have usually been handled by warehouse management systems (WMS) while warehouse control systems (WCS) managed material handling equipment. Although WMS were primarily used to plan and manage inventory and locate goods in the warehouse, WCS systems were deployed mostly to control and manage the movement (relocation) of materials and inventory in real time.

To fulfill their duties, WCS systems are integrated with automation controllers (PLC) and devices like conveyor belts, sorters, carousels, and automatic warehouse racking systems. WMS systems, on the other hand, were usually connected to a company’s administrative system (such as ERP systems) and mainly documented item and order movements, tracked inventory in real time, and ensure the optimal use of material, machine, and labor resources.

Modern Smart Industry systems are currently the result of a combination of the functionalities and features of both WMS and WCS. As a result, they can create even greater throughput, increased storage agility and inventory management processes in supply flows, which would be impossible had WMS or WCS been used independently.

However, current distribution centers and warehouses need to manage not solely equipment, people, and inventory but also the entire supply process and the individual operations in the supply processes —from goods receipt through put-away and storage to dispatch. For this reason, distribution warehouses are increasingly looking for new generation WMS systems, warehouse execution systems (WES) as opposed to traditional WMS or WCS systems.

Generational SHIFT in Inventory and Warehouse Management

WES systems can be seen as the logistics counterpart of the manufacturing execution system (MES). They also represent a natural evolutionary stage in the development of a company's information infrastructure and an example of the hybridization of new technologies. This is because WES systems are essentially a crossover product of WMS and WCS systems.

Looking at it from a digital transformation perspective, they represent a logical effort toward the vertical and horizontal integration of processes. The convergence of the company's control and data layers and the more intensive interconnection of individual functions creates synergies and contributes to wider optimization of processes than could be achieved with either WMS or WCS.

The more developed WMS systems already partly include more complex and agile material flow management, making WMS more like WES. Thanks to the close integration with the company’s ERP system, WMS systems automate the following functionalities:

- Order management

- Inventory management

- Materials and goods monitoring,

- Recording material receipt, put-away, storage, pick-up, and dispatch

The purely evidence-based method of processing and managing warehouse operations allows WMS systems only static labor management and resource utilization. WES systems achieve a significantly higher level of dynamics of management and optimization of resource utilization in this area, mostly due to their event-driven processing approach.

Some modular WMS systems can also dispatch management and integration into transport management systems (TMS). For WES, integration into TMS is already a part of the platform, as TMS is a part of the process management at the horizontal level.

For distribution companies, WES systems can allow them to work dynamically with received customer orders — sort and redistribute them according to the current demand to:

- Exploit available resources

- Eliminate downtime and operations without added value

- Meet maximum shipping requirements with respect to approved delivery times

For WES systems to efficiently manage and coordinate equipment, inventory, and human resources dynamically and in real time, to ensure the added value of WMS and WCS, they are often built on a cyber-physical platform with a decentralized and distributed architecture.

Therefore, they are essentially based on the Internet of Things (IoT), Internet of Services (IoS), digital twin technology, and multi-agent systems with elements of artificial intelligence (AI) and collective intelligence.

Using WES systems, ANASOFT digitalized the operations of a retail company supplying the HoReCa segment. ANASOFT implemented a complex management system for managing and monitoring production technologies, order-picking, and order dispatch to end customers. The WES system was integrated with the company’s PLC, ERP system, the e-shop platform, and the internal ECM system for document and invoice management.

Besides managing material inbound, receipt, put-away and storage, dynamic order-distribution, and production planning, the system autonomously manages order picking (management of warehouse equipment, warehouse operators, goods), equipment and material (bins of various sizes; bins for frozen goods) handling, order completion and their subsequent dispatch and shipping to end customers.

The fundamental benefit of WES is its ability to monitor the entire production process and individual technologies (automatic conveyors, scales, scanners). Not to mention its capacity to reduce the need for paper protocols and documents across the entire production and distribution process. In the warehouse, there is a more efficient management of inventory, picking and shipping of orders, even in the case of very diverse and voluminous orders.

Dynamization of Process Management

Due to the dynamic process management, the Smart Industry system (WES module) can flexibly change the sequence of customer and production orders. In manufacturing companies, the horizontal process chain is extended by MES or manufacturing operations management (MOM) systems, a management process almost akin to a comprehensive supply chain management process. This horizontal integration already includes additional modules (or systems) for quality control or maintenance management.

In manufacturing companies, this facility means that if material or goods are delayed in entry (material coming from an external environment), WES operatively processes this information from TMS (or another subcontractor system) and prioritizes available materials that can be processed before the delayed inventory arrives, thus eliminating downtime and reducing delivery delays. The WES system also sends requests to change the order of production orders to the MES system to ensure as smooth manufacturing process as possible.

Such operations system, built on the principle of vertical and horizontal integration, represents a modular Smart Industry solution, which synchronizes the management of manufacturing (production units) and supply processes (logistics operators) — and by extension, the entire flow of materials and products (input components, semi-finished products, finalized products for shipping).

For manufacturing companies, this solution affords a completely autonomous operation, and ANASOFT has managed to create it for a wheel assembly company. The result of the project is the autonomous management of wheel assembly processes based on (Just-in-Sequence / Just-in-Time) the production plan of the customer, i.e., a car factory.

The Smart Industry system in the wheel assembly company optimizes the manufacturing and supply processes by increasing productivity, reducing manufacturing equipment downtime, and minimizing errors and failures (scraps). By standardizing and optimizing production processes, a fixed production cycle of 22 seconds was achieved on the wheel assembly shop floor for the production of one wheel (if necessary, the assembly cycle can be pushed even under 20 seconds). The Smart Industry system is also connected to an automatic (unmanned) warehouse for finished products that stores finished wheels until their are dispatched into the car factory.

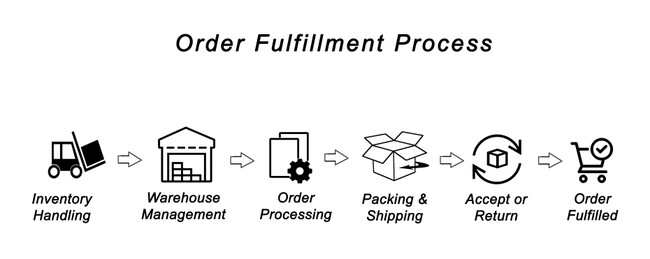

Order Fulfillment Process (source: Shutterstock)

Smart Automation of The Fourth Industrial Revolution

Today’s digital transformation era is also changing the very concept of automation as it is gradually evolving into smart automation. The drives are mainly exponential technologies like the Internet of Things (IoT), Internet of Services (IoS), digital twins, and artificial intelligence (AI) and advanced intelligence tools.

This era marks the evolution of supply management and order fulfillment, which also includes WES systems, that foreshadows the features that will soon be crucial for businesses. The World Economic Forum (WEF) summarizes these features into three categories:

- Connectivity

- Intelligence

- Flexible automation

(Inter)Connectivity in manufacturing and logistics means the interconnection of machines, equipment, people, materials, products, information and communication technologies and systems, and last but not least, data.

Artificial intelligence will trigger a revolution similar to that of the Internet in manufacturing and supply chain processes. Various forms and types of machine intelligence, which are already entering industrial and supply processes (the basis of smart automation), will be used in decision-making, planning, management, and control processes. The three essential features — components of flexible automation — are as follows:

- Customizable automation

- Adaptable robotics

- Automatic reconfiguration of tools and equipment

All three, together with modern Smart Industry systems, take intelligent operations management to the next level, toward autonomy. Autonomization with new technologies ensures the management of material flows in a dynamic environment in which WES systems synchronize the activities of automated equipment and labor.

Besides increasing the throughput of logistics flows and preventing failures, shutdowns, or emergencies with operational intelligence and process agility, these systems simplify communication throughout the warehouse while reducing the need for manual planning and interventions by warehouse or logistics staff.

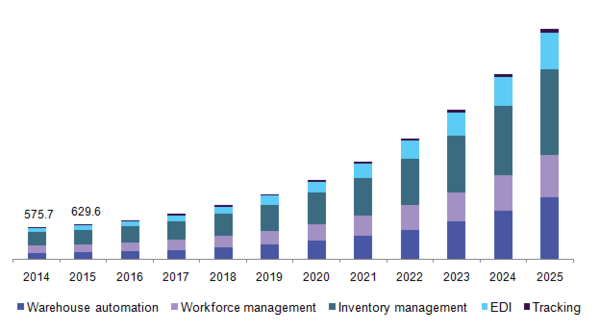

U.S. IoT in warehouse management 2014-2025 (USD Million) (source: Grand View Research)

READ MORE