How to Improve Warehouse Performance with Dynamic Order Picking [Case Study]

2020-04-28

Order picking expenses can account for up to 55% of a warehouse’s total operating cost. Digital technologies enable to optimize not solely operating costs, but also the efficiency, quality, and flexibility of warehouse processes.

Manufacturing and logistics companies supplying materials and components to factories equally face the issue of stocking up capital and materials in their inventories. To avoid this problem, they strive to ensure seamless flow of supply according to actual demands. The very same challenge is faced by enterprises and distribution companies as well as e-shop operators given the e-Commerce boom.

Warehouse providers have to prepare inventory and ship orders on time and without errors. Warehouses and transhipment centers process countless quantities of orders for retails and wholesales and ship highly variable items in rapidly fluctuating volumes.

E-shop owners and operators have to deal with shifting customer preferences that directly impact the portfolio and upsurge of item variability. Besides, they are also on constant pressure to improve service quality, reduce delivery limits, and enable the possibility of additional modifications for already placed and processed orders.

When current warehouse processes and dispatch logistics become unsustainable long-term, or the quality of orders and delivery time become unsatisfactory, enterprises should innovate established picking order processes and boost the performance of inventory management.

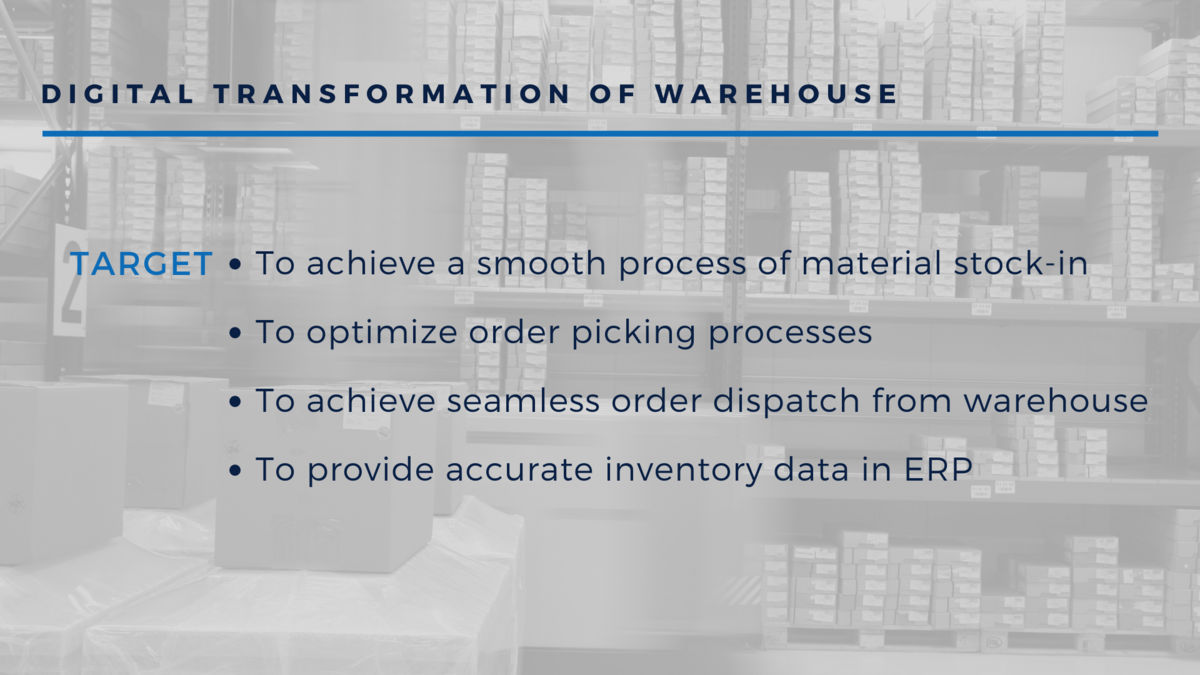

ANASOFT participated on a project of the digital transformation of the warehouse logistics processes of a business selling small and large items of furniture in large quantities and varieties for two target clienteles: customers (B2C) and processors (B2B). The company had decided to optimize its warehouse processes to improve the efficiency of inventory management and picking order tasks that would augment the volume and variety of sold items.

The main warehouse tasks comprise of inventory receipt from suppliers, followed by put-away; processing orders received via e-shopping platforms, order picking and completion, dispatch, and shipping.

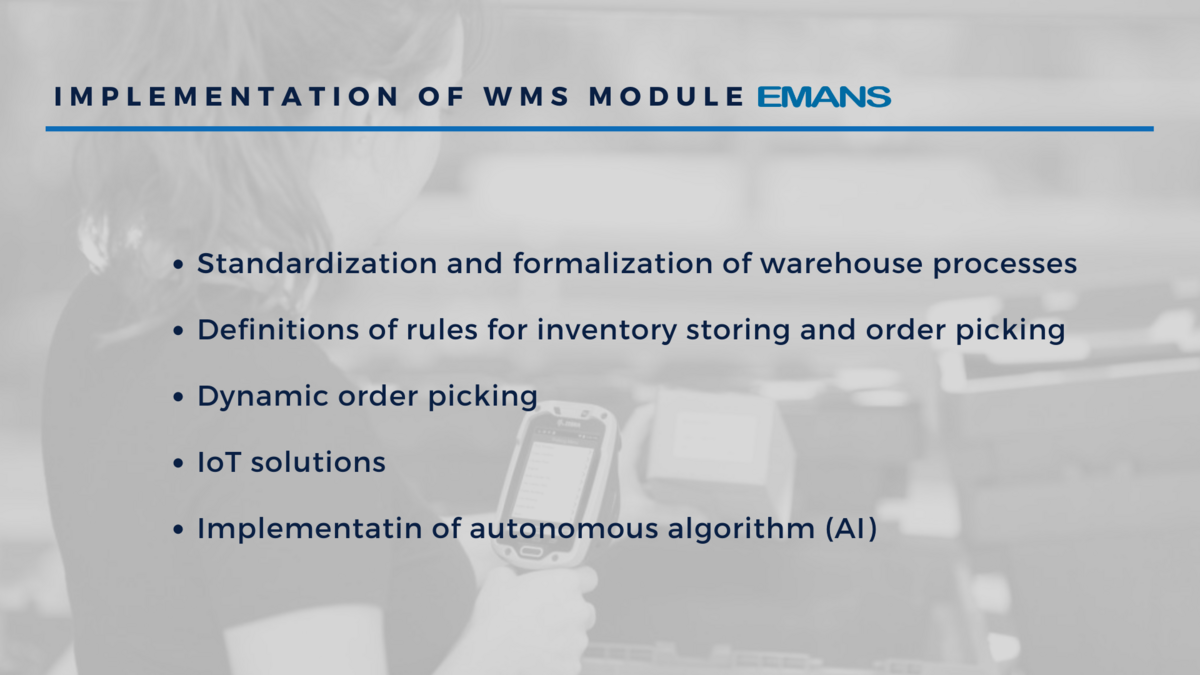

The company chose Smart Industry solution EMANS to automatize and optimize their warehouse management processes apropos inbound and outbound logistics. EMANS, as a system of intelligent logistics and warehouse management, has broad functionalities including inventory and labour management within EMAN´s WMS module.

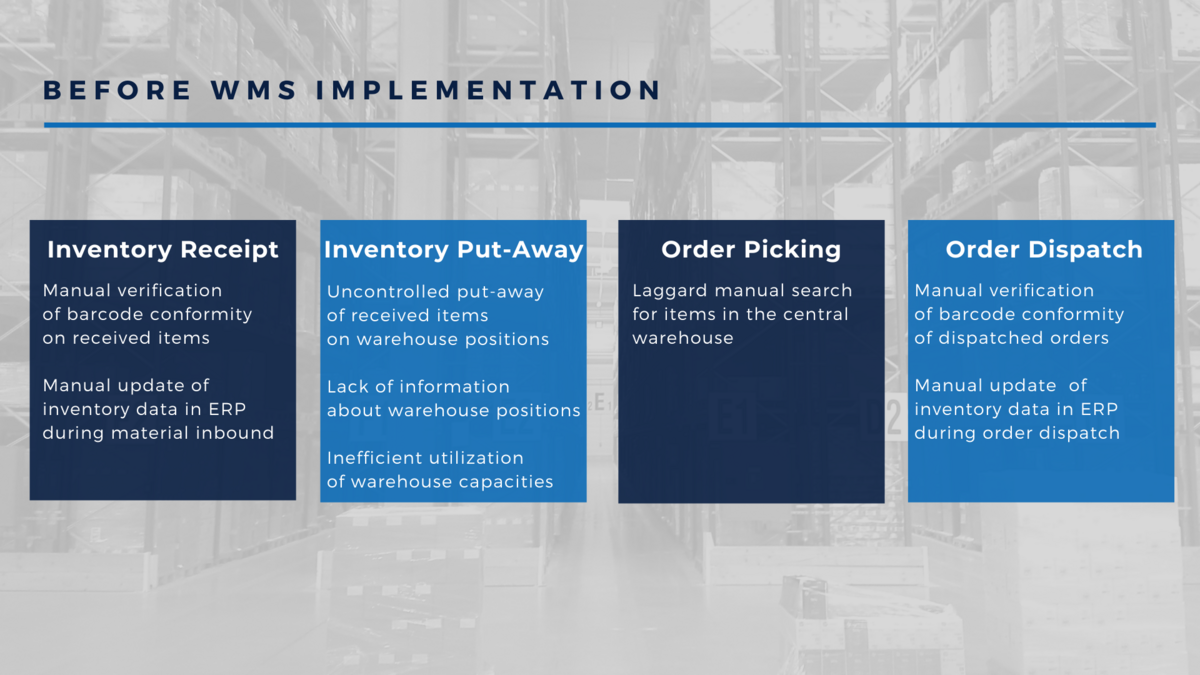

The company had been using an ERP system, so implementation hinged on the successful integration of EMANS with ERP. The incoming and outgoing items were manually registered into the ERP system, same for the inventory control. Also, warehouse staff did not know the precise location of stocked items, primarily because all items were stored in identical boxes. Overall, the absence of a proper system increased non-productive time for order preparation and picking.

Warehouse Management System

Digitalization, virtualization and Industry 4.0 technologies significantly impact the automation of logistics processes. The WMS module of EMANS standardizes and formalizes inventory receipt, put-away, and picking processes. The project of digitalization and EMANS implementation enabled the transformation of the company’s uncontrolled warehouse into a controlled one. After implementing the WMS module and defining warehousing rules, the system EMANS can manage the put-away processes optimally and at the same time, sort order picking processes according to prevailing priorities.

Supplying WAREHOUSE

The operator uploads warehouse receipt of delivered items into the EMANS system and then identifies items with a scanning device when receiving, classifying, and storing incoming goods. The system EMANS automatically sends information about received goods to the company’s ERP to update the inventory records immediately.

Warehouse staff can have several receipt protocols opened at the same time while the Smart Industry system oversees inventory positioning in the warehouse based on pre-defined criteria, such as turnover rate, weight, and size of goods. EMANS automatically registers every movement in the company´s inventory and order transfers.

Dynamic ORDER Picking

The important part of the supply process is order preparation—order picking. Order picking is generally considered a laborious and costly activity in every warehouse. Order picking expenses can account for up to 55% of a warehouse’s total operating cost. This makes it crucial to implement a cost-effective and efficient form of picking.

The system EMANS optimizes order preparation tasks using dynamic order picking. Warehouse personnel uploads all delivery orders into the scanning device and the Smart Industry system will arrange them based on priority, after which EMANS identifies the warehouse positions of items to be dispatched. After identifying the correct item, an employee would pick up the required quantity, confirm the picked items in type and quantity, and then continue to the next task on the order picking list.

The EMANS system also selects the shortest route in minimizing travel distance during the order fulfillment. This provision lets warehouse personnel skip warehouse zones not relevant to the order, thus reducing the overall picking time per order. Besides selecting the shortest picking route, employees can choose to sort items by their sizes—heaviest/largest to lightest/smallest—to make material handling more ergonomic. During order picking, the system automatically readies all accounting data for the company’s ERP system to streamline administrative-financial processes.

general Improvement of Warehouse PERFORMANCE

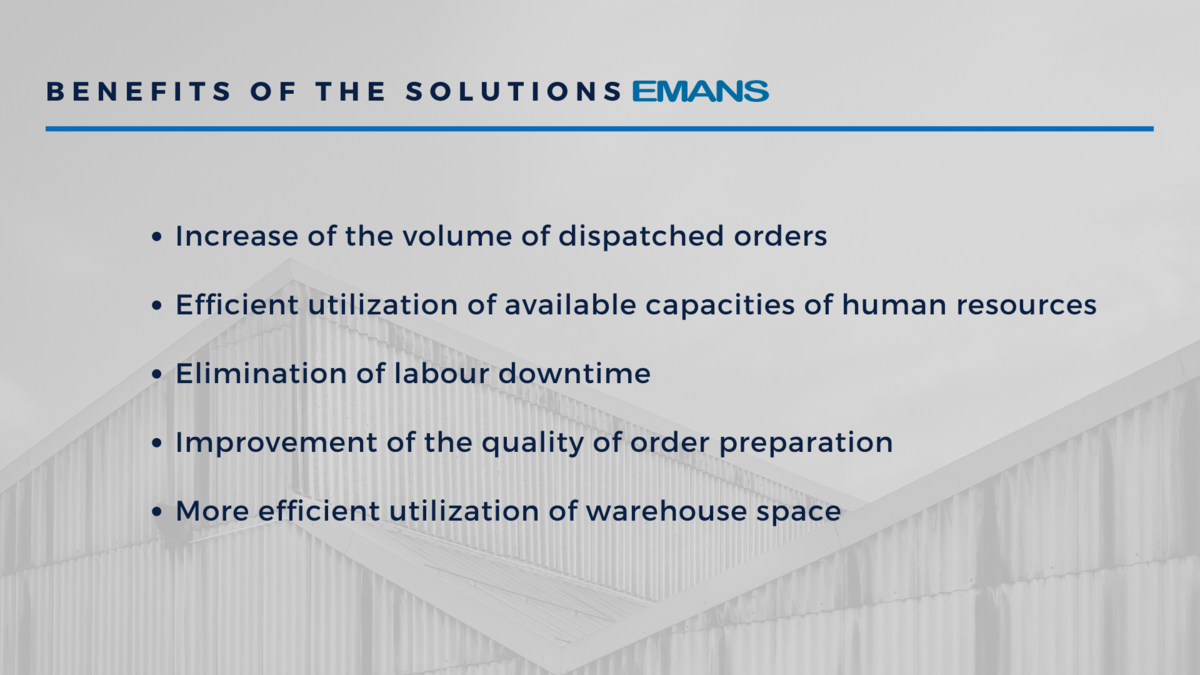

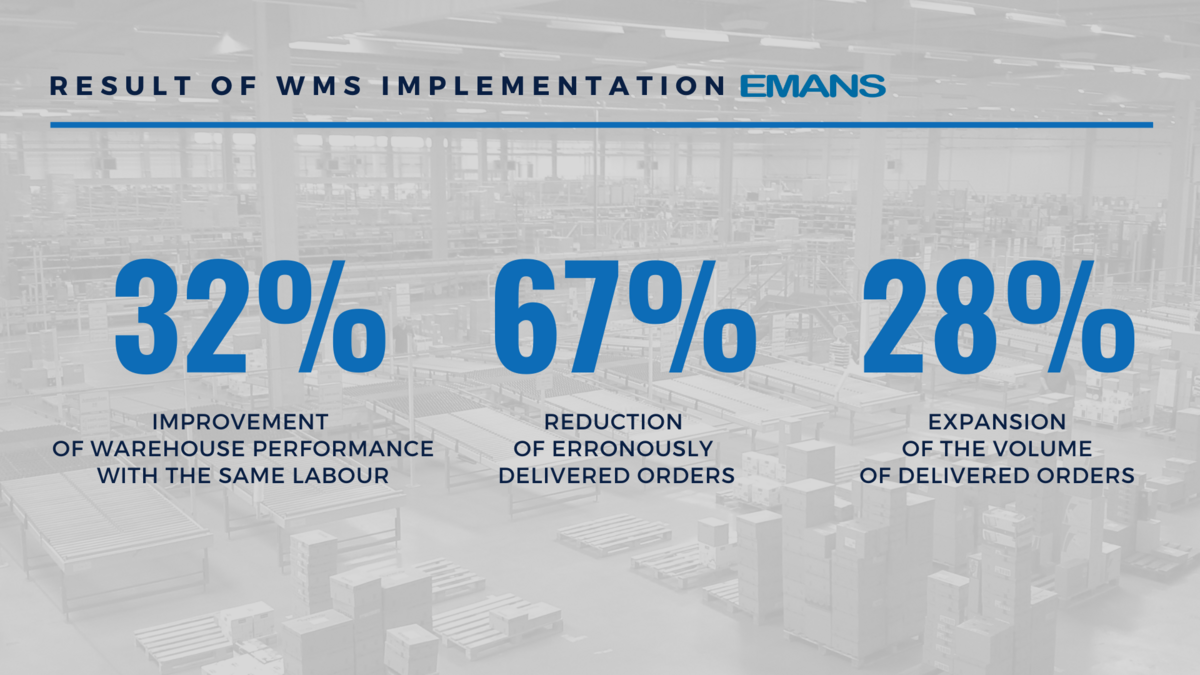

The implementation of the WMS module of the Smart Industry solution EMANS enabled dynamic and automatized order picking process and optimized inventory and labour management that contributed to the overall improvement of the warehouse productivity.

Employees have access to updated and precise inventory information at all times and can thus flexibly manage the warehouse supply, thereby preventing the unexpected shortage of offered goods. They can also track all movements, in and out of the warehouse, in real-time while the system automatically updates the ERP in preparing the delivery of orders.

Digitalization of the company’s warehouse processes with Smart Industry solution EMANS enables effective management of available human resources. The system manages warehouse operators in real-time and adopts put-away and order picking processes to current circumstances, order priorities, and delivery times.

By removing the time spent searching for items as in uncontrolled warehouses, the system’s algorithms eliminate non-productive time, achieved by picking the fastest routes to items. In addition, the system enhances the quality of the whole process since it eliminates the occurrence of mix-ups during order preparation—yet another factor diminishing the overall order dispatch cycle.

Besides the expedited item-based inventory check, EMANS provides managerial data output—mostly key indicators for accurate decision-making, such as tracking inventory turnaround rate, or overall warehouse labor effectivity (OLE). Moreover, the Smart Industry solution EMANS optimizes the space in the warehouse in order to extend the available storage capacity.

read more

![How to Improve Warehouse Performance with Dynamic Order Picking [Case Study]](/assets/components/phpthumbof/cache/How_to_Improve_Warehouse_Performance_with_Dynamic_Order_Picking_Case_Study.5c0a8d26dc0f69d9d935465d126a1e5e.png)