The Road to Automated and Intelligent Warehouse

2018-07-23

The digital transformation of enterprises and digitalisation of manufacturing processes are fast becoming the norm and necessity not only for expansion purposes but also for long-term sustainability, regardless of size or nature of enterprise.

Due to the above-stated reasons, one of the results of the PwC Automotive Supplier Survey comes as no surprise: a third of respondents anticipate the adoption of the concepts of Industry 4.0 over the next five years.

In terms of logistics, the demand is even more urgent. The ever-changing environment of the logistics’ industry continuously throws up new demands for quality, flexibility, and types of the services provided by logistic companies. Moreover, the incessant pressures caused by enterprises’ operational costs force them to re-evaluate their business models and revise both the ongoing processes and operations to ensure the continuity and reliability of the supply chain.

The Digital Transformation of Logistics Processes

Digitalisation and innovative technologies are becoming irreplaceable tools for expected and requisite change in the supply chain. They make capacity optimization, performance boost, quality improvement, and flexibility of the entire supply chain possible. It’s for these rationales that enterprises are increasingly yearning for intelligent solutions capable of harnessing the potential of digital technologies.

The digital conversion of processes and implementation of technologies obtainable under Industry 4.0 or Smart Industry solutions do not necessarily need to be wholly and rapidly applied. The modularity of intelligent logistics solutions built on the principles of cyber-physical production systems allows the gradual transformation of the supply chain.

Logistics or dispatching/forwarding companies or enterprises that are innovating their internal logistics processes can thus immediately react to current demands via a concrete part of the supply chain. Companies often employ personalized solutions in anticipation of expected market shifts, upcoming challenges; or in reaction to increased demand for variability and customization of services from clients.

The digital transformation of logistics processes can unspool in the same fashion as the digitalization of enterprises. Companies can start with a solution for data collection and analytics and then proceed to the horizontal integration of processes followed by the vertical integration of processes. And ultimately, finalize the process of digital transformation with auto-optimization solutions for equipment and systems.

road to Warehouse 4.0

The most common reasons for modernization and automatization of warehouse management processes are as follows: excess supply of stock, large quantities of different types of items, and complicated access to information whether it is the evidence of goods turn-around, complaints, give-backs, expiration date, or others.

-

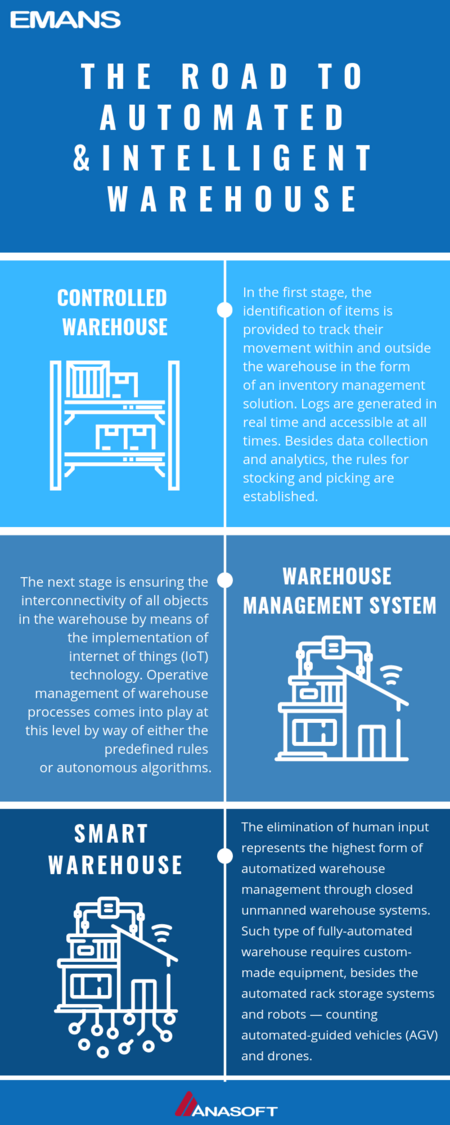

Controlled Warehouse

In the first stage, the identification of items is provided to track their movement within and outside the warehouse in the form of an inventory management solution. Logs are generated in real time and accessible at all times.

Besides data collection and analytics, the rules for stocking and picking are established. Hence, through the execution of these rules, warehouse systems can effectively and optimally manage the positioning of items in the warehouse and also prioritize tasks and operations.

Remarkably, this solution converts an uncontrolled warehouse into a controlled warehouse — this also applies to storage facilities situated on workstations (outside the supermarket/the main warehouse).

In such type of warehouse solution, logistics operators communicate directly with the informational system through an augmented human-machine interface either via terminals or mobile devices.

-

Intelligent Warehouse Management System

The next stage is ensuring the interconnectivity of all objects in the warehouse by means of the implementation of internet of things (IoT) technology. Operative management of warehouse processes comes into play at this level by way of either the predefined rules or autonomous algorithms.

Materials/products are not moved anymore according to a static regulation in the warehouse; algorithms of a warehouse management system, on the other hand, evaluate the demands in real time and based on a complex set of criteria, such as current occupancy of storage positions, the degree of turn-over, or seasonability.

The relevant data are then gauged considering the current conditions and previous development of selected indicators that point to factors which enable dynamic management of storage and picking processes.

Concerning operative management, this solution offers the operating personnel wider features of visualization as the personnel is precisely and in detail navigated by the information system in performing tasks.

-

Smart Warehouse - Unmanned Warehouse System

The elimination of human input represents the highest form of automatized warehouse management through closed unmanned warehouse systems. Such type of fully-automated warehouse requires custom-made equipment, besides the automated rack storage systems and robots — counting automated-guided vehicles (AGV) and drones.

Each piece of equipment is auto-organizable, and its activity is coordinated based on the principle of a multi-agent system. Also, the system’s platform provides the infrastructure for interaction with all equipment in such a distributed system.

read more