DEDOLES: Massive Expansion of Online Retail Fueled by Intelligent Technologies [Case Study]

2020-11-25

Dedoles is one of the most thriving central European online stores that has managed to successfully cross over to other European markets. With a massive expansion on the horizon, the company decided to innovate and automate its inventory and warehousing processes, leveraging the technologies of the Fourth Industrial Revolution and intelligent logistics.

The company Dedoles, based in central Europe, creates and sells original clothing with colorful designs. It is currently one of the region’s fastest-growing companies in the e-commerce and retail segment.

Its humble beginnings as a DIY e-shop date back to 2012, when founder and CEO Jaroslav Chrapko took out a consumer loan worth €5,000 to get the business running. However, Dedoles' recent growth and international expansion have been exponential.

When sales reached almost €6 million in 2018, management had every reason to be proud, but the very next year sales climbed to €15 million.

Dedoles plans to double that amount again in 2020; meanwhile, 2019 saw the company exceed the threshold of half a million customers.

Dedoles has also been wildly successful in fulfilling its vision to expand into European markets. The company currently operates in 20 countries.

Chrapko, the founder and CEO, sees great room for growth in the European Union, as e-commerce is a segment which is relatively "easy to scale to other markets and reach new customers with low expenses."

RENAISSANCE OF THE E-SHOP

Since 2014, the company has evolved following a strategy of gradual innovation. "We continued to innovate, but we have realized that if we do not start working with a mandatory marking of goods via EAN codes and also with the three-dimensional marking of warehouse positions with barcodes and a system that coordinates and automates a huge number of basic procedures, we cannot expand further," explains Chrapko. He admits that they already had the potential to sell 30,000 to 40,000 additional orders; however, their logistics processes at the time would not have been able to cope with such demand.

Jaroslav Chrapko calls the years 2014, 2015, and 2016 a period of rapid growth, when a partial inventory automation led the business to pivot to ERP-driven processes.

The company purchased portable scanners and racks, defined precise warehouse positions, and prepared supply processes, a complex of actions Chrapko calls the "basics of logistics." Dedoles automated elementary processes, such as the creation of invoices and feeds between the ERP system and the e-shop platform, which Chrapko identified as another basic prerequisite for rapid growth.

As the CEO and founder further explains, to achieve exponential growth, his company had to focus on three main areas, which have since become the pillars of their current success:

- original products,

- the brand,

- and logistics.

These three areas entail crucial processes of every optimally running online retail operation:

- product innovation,

- marketing and customer care,

- and inventory and warehouse management system.

In the interest of successful international expansion, Dedoles therefore found it necessary to streamline, optimize and automate warehousing processes and order-fulfillment logistics.

With the advancing expansion and a growing portfolio of fast-moving and variable inventory, the old model of uncontrolled warehouse management was no longer sufficient for the soaring daily volumes of customer orders. Furthermore, warehouse order pickers were beset by unnecessary movements and errors during fulfillment processes.

Dedoles estimated that it should be able to process up to 9,600 orders a day during seasonal peaks, which accrues to around 40,000 items. Therefore, the company decided to extend its core digital ecosystem to include inventory and warehousing processes through an intelligent logistics solution, thus automating and optimizing its supply and logistics management.

OPERATIONAL INTELLIGENCE OF WAREHOUSE

With these goals in mind, the fast-growing online retailer approached ANASOFT's Smart Industry division, which has long been dedicated to digitalisation and intelligent automation of logistics and manufacturing processes. Dedoles' goal was to transform its in-house logistics into a more agile warehousing process that would meet its growing order fulfillment needs.

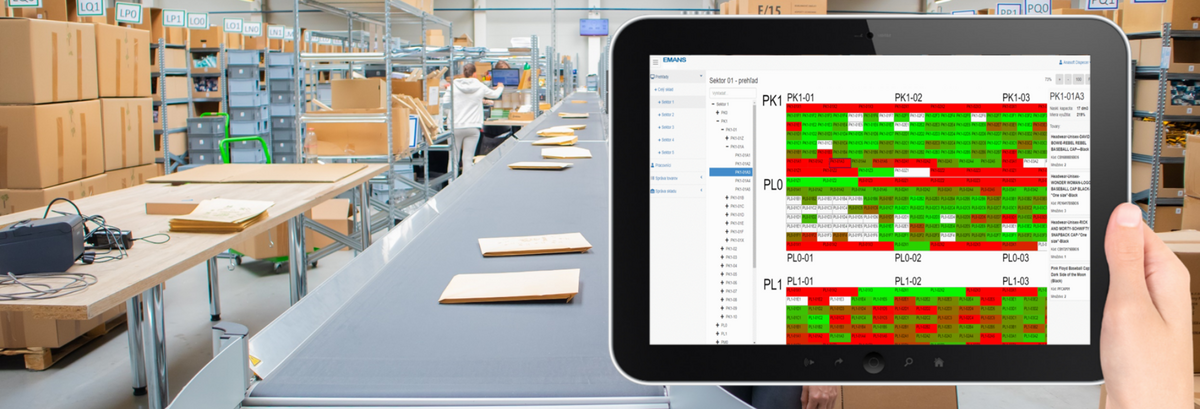

"The new logistics system was to be created under the principles of intelligent logistics and the Industry 4.0 concept so that the system could respond dynamically to customer requirements in all markets," says Peter Bílik, Smart Industry solutions designer at ANASOFT. The center of Dedoles' digital ecosystem has become the logistics management module of the Smart Industry solution EMANS developed by ANASOFT.

Peter Bílik explains: "We are not delivering a standardized WMS [warehouse management system] module, but an advanced system for inventory, warehouse, and supply automation – a WES [warehouse execution system]. It is one of the modules of our Smart Industry platform EMANS, and its functionality is adapted and calibrated to unique features and parameters of the client's warehouse and logistics. The whole order fulfillment process – including receipt, put-away, and picking up – is carried out not only from the point of view of the management of warehouse transactions, but also as complexes of actions grouped into jobs that are dynamically operated by the internal LMS [labor management system] module of our Smart Industry solution."

The new intelligent platform for warehouse and supply process management has enabled Dedoles to transform a previously uncontrolled warehouse into an agile and dynamic warehousing enterprise by using the principle of mirroring stock-keeping units (SKUs) and deploying sophisticated dynamic slotting algorithms.

The principle of stock mirroring had already been employed to design the new diversified warehouse arrangement by ANASOFT before the Smart Industry system was deployed. This approach formed the basis for the division of the warehouse into several zones. The purpose of zonation was to allocate the same stock of high-turnover items into several different inventory positions in as optimized a manner as possible.

Such placement prevents warehouse operators from interfering in each other's order-picking jobs. Such a solution of in-house logistics is ideal for businesses and enterprises that warehouse and dispatch a wide range of diverse and high-turnover goods in terms of fast and error-free order-fulfillment cycles.

Furthermore, the method of dynamic slotting is particularly suited for online retailers who sell fast-moving and highly variable goods with increased product fluctuations and want to optimize their order fulfillment process. Dynamic slotting is applied to the receipt of goods and the subsequent put-away and storage strategy.

Goods that the system projects will come into high demand are stored in zones closer to the conveyor for dispatching customer packages. Dynamic slotting, therefore, helps increase the efficiency of the order-picking process (and therefore the whole order fulfillment cycle) and shortens lead times of multiple simultaneous order pickings.

Just as dynamic slotting is the most effective warehousing strategy for businesses with fast-moving goods, cluster picking has proven to be the most effective order-picking strategy in the retail and e-commerce industry. Cluster picking processes are also driven by intelligent algorithms.

Smart Industry system EMANS prepares picking lists for warehouse order pickers and operators based incoming customer orders. Items related based on warehouse location are combined into a job for a warehouse order picker. In a single pass through the warehouse, an operator is able to pick several orders.

The system prepares picking lists and jobs for a group of operators and proceeds to effectively manage their tasks while navigating the whole group in the warehouse via real-time portable scanning devices. Therefore, the system guarantees precise and quick picking of received orders, including the processing of special orders with designated priorities.

When preparing pick lists (schedules and jobs), the system takes into account a number of ergonomic parameters, especially in order to prevent overburdening of employees and to preserve their working comfort while fulfilling the tasks.

Up to 40 operators can pick up orders in the warehouse simultaneously. They are coordinated so as not to interfere with each other's tasks and routes while carrying out assigned jobs. This synchronization of pickers' work contributes significantly to eliminating downtimes.

The implementation of Smart Industry system EMANS as a warehouse execution system, which utilizes dynamic storage and order-picking strategies, resulted in a 170% increase in warehouse throughput with a minimal increase of staff compared to the previous arrangement of uncontrolled warehouse management.

DIGITAL TWINS AND COLLECTIVE INTELLIGENCE

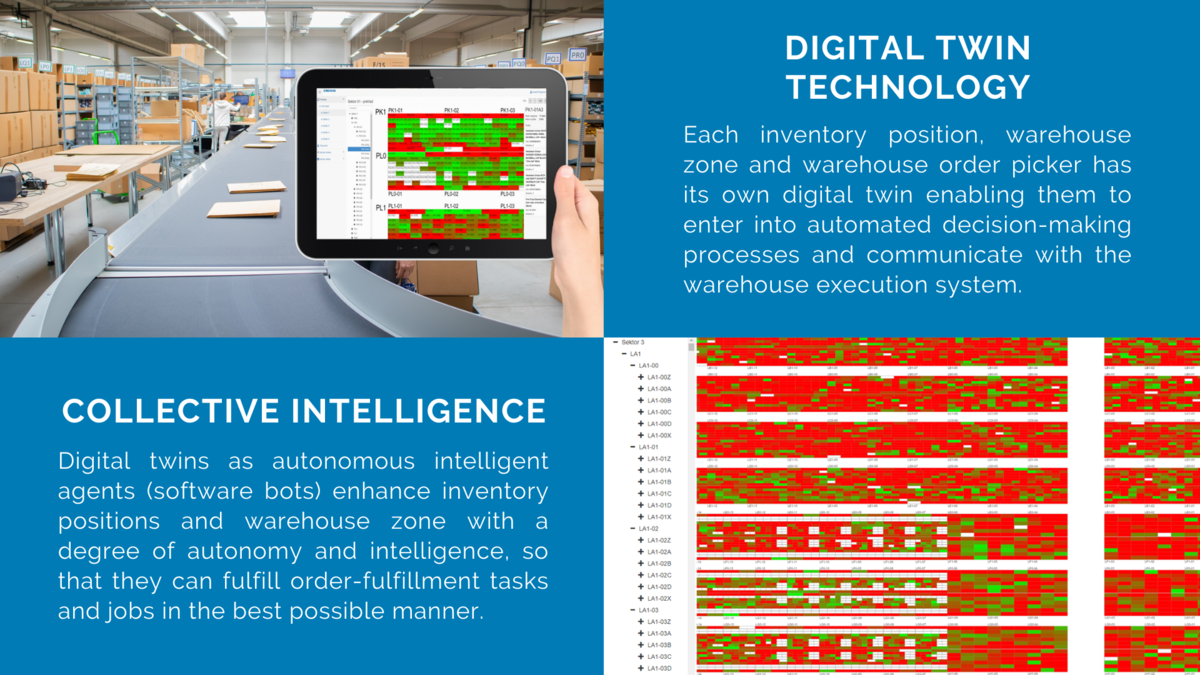

Smart Industry system EMANS represents a next-generation cyber-physical platform. The system employs cutting-edge technologies, including the Internet of Things (IoT) and Internet of Services (IoS). The WES module also utilizes the technology of digital twins, which is currently one of the hottest trends of the Fourth Industrial Revolution and intelligent logistics.

Smart Industry system EMANS creates a virtual copy of the entire warehouse, which gives each warehouse position (as well as each warehouse zone) its own digital twin – an autonomous intelligent agent, or software bot. This way, each warehouse position acquires a form of its own intelligence and autonomy, allowing it to enter into automated decision-making processes and communicate directly with the warehouse's operations management system, EMANS.

The inventory positions participate in the preparation of order-picking schedules and tasks directly via their digital twins, since the positions track precisely what types of items and in what quantities are stored on them. They also track how reservations on SKUs are changing in real-time, data which can further be utilized for optimizing order-picking processes.

Furthermore, the warehouse's digital twins can proactively monitor the level of available stock as well as the accessible capacity of each position, both of which parameters are taken into account during put-away processes of incoming inventory. Digital twin technology provides increased transparency and clarity (visibility) for the warehouse while monitoring the utilization of inventory positions in real-time.

Digital twins are becoming an indispensable technology to effectively manage order fulfillment processes with large volumes especially in warehouses of Dedoles' size (approximately 25,000 inventory positions). Digital twin technology becomes more important when the operational management system needs to make dynamic, fast, and, above all, precise decisions on an extensive number of incoming orders and high turnover of inventory.

Besides warehouse positions and zones, mobile order-picking workstations equipped with portable scanning devices have their own digital twins as well. Digital twins of workstations effectively arrange tasks for order pickers based on current put-away and picking plans. Because these devices have their own decision-making autonomy, they also function as tools of the warehouse´s collective intelligence.

Since intelligent agents of mobile order-picking workstations, basically digital twins of the warehouse pickers, operate on an autonomous basis, they can be dynamically added or removed from warehouse and inventory processes as demands fluctuate.

Dedoles thus achieves flexible scalability in its warehouse operations. If the company expects a greater influx of orders (for example during seasonal peaks), the number of employees can be expanded immediately, for example from 20 warehouse order pickers during a standard operation to 35 pickers for the season, without the need for exhaustive (re)training or onboarding as all the operations are already standardized and formalized.

FOURTH-GENERATION RETAIL (R4.0)

Dedoles founder and CEO Jaroslav Chrapko argues that the increasingly strong competitive advantage of online retailers will be their own network of brick-and-mortar shops. "People want to start their shopping experience online, explore and compare prices, options and promotions, and when they find the items they want, they prefer to pick up the order in person," says Chrapko, adding, "Almost two thousand people come to the company's central warehouse each year to pick up orders in person."

Therefore, modern retail businesses already have to combine diverse sales strategies that stem from the concept of omnichannel distribution. One of these strategies is "click & collect," a hybrid of online and offline customer experience. Furthermore, omnichannel distribution entails feeding a network of brick-and-mortar stores or pop-up kiosks from the same warehouse that online customer orders are fulfilled from.

Dedoles is utilizing the warehouse execution system of the Smart Industry system EMANS to feed its network of kiosks. In practice, this means that the system differentiates between retail and wholesale orders when preparing order-fulfillment plans and tasks and tailors individual order-picking strategies to ensure smooth and fast deliveries on a sustainable basis.

Access to accurate and up-to-date data has become a fundamental requirement in modern retail management. Managers at Dedoles have all the numbers available in real-time including analytics and reports on daily performance, incoming order fulfillment, and order pick and dispatch speed, along with analyses of how orders are decomposed into individual picking plans and tasks.

With all of this data available, managers and supervisors can accurately predict how many workers must be deployed on a given day in order to have all incoming and received orders properly picked and dispatched within standard delivery times.

Dedoles has become a leader in scaling up processes, both business and logistics, driven by new technologies. At the same time, the company is setting new standards for online retail in the niche-to-global category.

Dedoles had 600,000 active customers at the end of 2019, and by September 2020, the company had managed to pass the stunning frontier of 1,000,000 customers.

In 2019, when Dedoles shifted to intelligent and dynamic logistics management, the company managed to achieve annual sales of €14.6 million, an increase of 154% compared to the previous year. The projected sales for 2020 are anticipated to pass the threshold of €41 million, demonstrating the degree of rapid expansion and growth propelled by the significant contribution of the intelligent warehouse solution.